How to choose a right screen deck

Dec 10, 2025Today we are glad to show you different types of screen decks: tines, bofor bar, punch plate and wire mesh.

Tines:

Application Occasions: Primary screening, heavy-duty conditions with high material impact intensity; where high screening precision is not critical, typically installed on the top deck of the screen box.

⭐ Clogging Prevention: The large openings and smooth bar surfaces facilitate easy material passage.

⭐ Robust Structure: Manufactured from high-strength spring steel or wear-resistant alloy steel. Compared to wire mesh, the tines plate diameter provides a greater wear allowance, resulting in a longer service life.

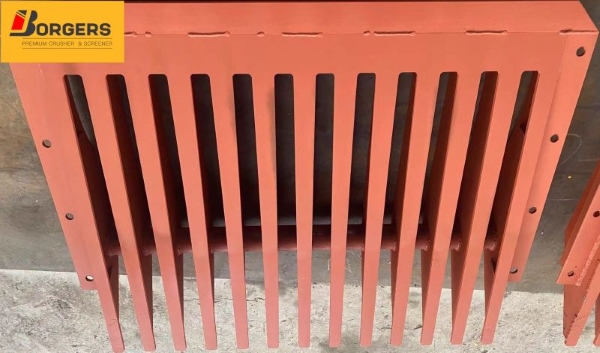

Bofor bar:

Application Occasions: Primary screening, heavy-duty conditions with high material impact intensity.

⭐ Made from very high-strength wear-resistant steel, the bofor bars have a large cross-section, capable of withstanding the massive impact force of multi-ton bulk materials falling from height without breaking or deforming permanently. Its wear life far exceeds that of ordinary screens.

⭐ Its primary function is to pre-screen and remove "under size" material (e.g., soil, fines) that does not require crushing before feed enters the primary crusher, and to direct "oversize" material of suitable size directly into the crusher, thereby significantly improving the efficiency of the entire crushing and screening circuit and reducing crusher load and wear.

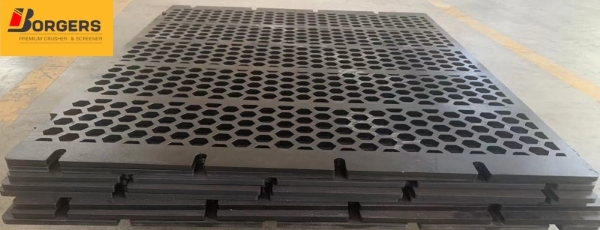

Punch Plate:

The screen life for rubber is usually between three and five times that of woven wire, and in some instances significantly more. Polyurethane meshes correctly selected can expect a life of perhaps twice that of rubber.

⭐More evenly distributed wear and longer life.

⭐Less tendency to blind due to the smooth surface.

⭐Less tendency to peg owing to the absence of upward diverging aperture walls inherent with round wire.

⭐Apertures are not restricted to square and rectangular (as with woven wire), and the perforations are able to be staggered at right angles to the material flow, and being staggered, present a greater opportunity for the particles to find an aperture. Perforated plate can also be provided with blank wear areas to protect the deck frame cross members.

⭐The smoother surface accelerates particle velocity (typically by about 10% above that of woven wire) resulting in a thinner bed depth.

⭐The smooth surface will cause less interference with stratification and promote screening efficiency.

Wire mesh:

Wire mesh is a widely accepted screening surface. Its advantages include a relatively low cost, it is available in a variety of wire diameters, materials, weaves, and is light in weight. Disadvantages include short wear life under certain conditions, a tendency to blind in certain types of weaves and high maintenance.

Wire mesh common weave styles:

⭐Plain weave: also called as double crimp, regular crimp and plain weave. This is commonly used when other weaves cannot be furnished because the wire diameter is too large in relation the opening size.

⭐Intermedia crimp:also called as corrugated crimp. This gives a rigid mesh when the aperture is large in relation to the diameter of the wire.

⭐Double lock: the most efficient weave for heavy duty screeners when the ratio between opening width and wire diameter permits its use.

⭐Flat top: also called smooth top, a weave that is specially woven to produce a smooth flat surfaced screen(all the crimping being on the underside). this weave will normally last longer than screen cloths with surface crimps

⭐Arch crimp: it combines a relatively smooth surface with a fair degree of rigidity of construction. Commonly used for heavy duty screens when the ratio between opening width and wire diameter permits its use.

For more information about Borgers' screen deck and services, please visit our official website or contact Borgers service team.